HI! I’M ELEMENT AI.

Dimer Acid

Product Description

Dimer Acid, a dimerized fatty acid, is used in the production of resins and other industrial applications, offering properties like flexibility and toughness.

Product:

Dimer Acid

CAS:

61788-89-4

Synonym:

Dimerised Fatty Acid; Dimerized Fatty Acid; Dimer Fatty Acid

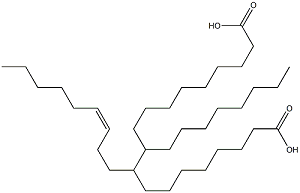

Structure:

Typical Characteristics

Appearance

Viscous liquid

Boiling point

300-350

Color

Light yellow

Density

0.92-0.94

Flash Point

>230

Melting point

-65 to -45

Molecular Weight

564.92

Odor

Mild

Purity

95

Refractive index

1.45-1.47

Solubility

Insoluble in water

Uses, Applications & Markets

Key applications

Markets

get a quote