Phenyl Ether-Biphenyl Eutectic

Product Description

Phenyl Ether-Biphenyl Eutectic is a mixture used in various industrial applications, primarily due to its thermal stability and heat transfer properties.

Product:

Phenyl Ether-Biphenyl Eutectic

CAS:

8004-13-5

Synonym:

Diphyl; Dowtherm

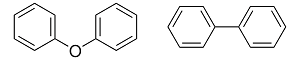

Structure:

Typical Characteristics

Appearance

Colorless to straw-colored liquid

Boiling point

257 °C

Density

1.06 g/cm3

Flash Point

123 °C

Melting point

12-14 °C

Molecular Weight

324.42

Odor

Disagreeable aromatic odor

Purity

99%

Refractive index

1.590

Uses, Applications & Markets

Key applications

Markets

get a quote

We Offer Phenyl Ether-Biphenyl Eutectic

in various grades

A few of the grades available are listed below:

Phenyl Ether-Biphenyl Eutectic used in many

industry applications

Phenyl Ether-Biphenyl Eutectic is a mixture used in various industrial applications, primarily due to its thermal stability and heat transfer properties. Here are some of its uses:

- Heat Transfer Fluids: This eutectic mixture is widely used as a heat transfer fluid in high-temperature applications, including chemical processing, pharmaceutical manufacturing, and plastic molding, where precise temperature control is essential.

- Thermal Storage Systems: It is used in thermal energy storage systems to store and transfer heat efficiently, especially in solar power plants and other renewable energy applications.

- Electronics Cooling: The mixture is employed in cooling systems for electronic devices and components, ensuring effective heat dissipation and maintaining optimal operating temperatures.

- Industrial Heating Systems: Phenyl Ether-Biphenyl Eutectic is used in industrial heating systems, including reactors and distillation units, where consistent and high-temperature heat transfer is required.

- Lubricants: It can be used as a high-temperature lubricant in mechanical systems that operate under extreme thermal conditions, providing lubrication and reducing wear and tear on components.

- Heat Exchangers: The eutectic mixture is utilized in heat exchangers to improve the efficiency of heat transfer between different fluids or gases in industrial processes.

- Synthetic Fiber Production: It is used in the production of synthetic fibers, such as polyester and nylon, where precise temperature control is crucial for the polymerization and extrusion processes.

- Specialty Chemicals: The mixture is involved in the manufacturing of specialty chemicals, where controlled high-temperature reactions are necessary to achieve desired chemical properties and product quality.