HI! I’M ELEMENT AI.

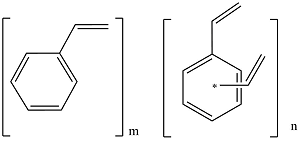

Styrene Divinylbenzene

Product Description

Styrene divinylbenzene (DVB) is a copolymer composed of styrene and divinylbenzene monomers, and it has various industrial applications.

Product:

Styrene Divinylbenzene

CAS:

9003-70-7

Synonym:

Benzene, divinyl-, polymer with styrene; Styrene, polymer with divinylbenzene

Structure:

Typical Characteristics

Appearance

White to yellow beads or powder

Density

0.29 g/cm3

Melting point

270 °C

Molecular Weight

409.5

Odor

Faint odor of styrene

Purity

99%

Refractive index

1.333

Uses, Applications & Markets

Key applications

Markets

get a quote

We Offer Styrene Divinylbenzene

in various grades

A few of the grades available are listed below:

Styrene Divinylbenzene used in many

industry applications

Styrene divinylbenzene (DVB) is a copolymer composed of styrene and divinylbenzene monomers, and it has various industrial applications. Here are some of its main uses:

- Adsorbents and Catalyst Supports: Styrene divinylbenzene is widely used as a matrix material for adsorbents and catalyst supports due to its high surface area, porosity, and mechanical strength. It serves as a carrier for active species in catalysts and helps to enhance their stability and reactivity in various chemical processes.

- Chromatography: It is utilized as a stationary phase in chromatographic columns for the separation and purification of organic compounds. Styrene divinylbenzene-based resins offer excellent selectivity, resolution, and durability in analytical and preparative chromatography applications.

- Ion Exchange Resins: Styrene divinylbenzene is employed in the production of ion exchange resins for water treatment, chemical purification, and separation processes. These resins can selectively adsorb or exchange ions from aqueous solutions, enabling the removal of contaminants and the recovery of valuable metals.

- Solid Phase Extraction: It is used as a packing material for solid phase extraction (SPE) cartridges in analytical chemistry. Styrene divinylbenzene-based SPE sorbents allow for the efficient extraction and concentration of target analytes from complex sample matrices, such as environmental, biological, and food samples.

- Hydrogenation Catalysts: Styrene divinylbenzene supports are employed in hydrogenation catalysts for the conversion of unsaturated compounds to saturated ones. These catalysts are used in various industrial processes, including the hydrogenation of edible oils, petrochemical refining, and pharmaceutical synthesis.

- Environmental Remediation: It is used in environmental remediation applications for the removal of organic pollutants from soil and water. Styrene divinylbenzene-based adsorbents can effectively adsorb hydrophobic contaminants, such as polycyclic aromatic hydrocarbons (PAHs) and chlorinated solvents, contributing to the cleanup of contaminated sites.

- Gas Purification: Styrene divinylbenzene is utilized in gas purification systems for the removal of impurities, such as sulfur compounds, volatile organic compounds (VOCs), and moisture, from industrial gases. Its high adsorption capacity and thermal stability make it suitable for applications in petrochemical, semiconductor, and air separation industries.

- Drug Delivery Systems: It is employed in the development of drug delivery systems, particularly for controlled release formulations. Styrene divinylbenzene microspheres or beads can be loaded with therapeutic agents and tailored to release them at a controlled rate, providing sustained drug release profiles for improved therapeutic outcomes.

- Biomedical Applications: Styrene divinylbenzene-based materials are used in various biomedical applications, including tissue engineering, cell culture, and protein purification. Their biocompatibility, mechanical properties, and surface chemistry make them suitable for biomedical scaffolds, cell encapsulation, and affinity chromatography.

- Composite Materials: It is incorporated into composite materials for reinforcement and modification purposes. Styrene divinylbenzene particles or fibers can be dispersed in polymer matrices to improve mechanical properties, dimensional stability, and heat resistance of composite materials used in automotive, aerospace, and construction industries.