Micro Crystalline Cellulose

Product Description

Microcrystalline Cellulose (MCC) is a refined wood pulp derivative widely used across various industries due to its excellent binding, stabilizing, and anti-caking properties.

Product:

Micro Crystalline Cellulose

CAS:

9004-34-6

Synonym:

Cellulose; Cellulose powder; Cotton linters

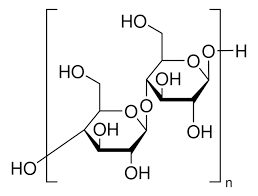

Structure:

Typical Characteristics

Appearance

White powder

Density

1.57 g/cm3

Flash Point

164 °C

Melting point

76-78 °C

Molecular Weight

324.28

Odor

Odorless

Purity

99%

Refractive index

1.504

Uses, Applications & Markets

Key applications

get a quote

We Offer Micro Crystalline Cellulose

in various grades

A few of the grades available are listed below:

Micro Crystalline Cellulose used in many

industry applications

Microcrystalline Cellulose (MCC) is a refined wood pulp derivative widely used across various industries due to its excellent binding, stabilizing, and anti-caking properties. It is a versatile ingredient with numerous applications in different sectors. Below are some of its industrial applications:

- Pharmaceutical Industry: MCC is a common excipient in tablet formulations due to its binding properties. It helps in forming tablets that are hard enough to withstand handling yet dissolve easily in the digestive tract.

- Food Industry: In the food sector, MCC is used as a texturizer, anti-caking agent, fat replacer, and stabilizer. It is commonly found in products like ice cream, baked goods, processed cheese, and sauces.

- Cosmetics and Personal Care: MCC is used in cosmetics as a thickener, binder, and bulking agent. It is present in various products such as face powders, creams, lotions, and toothpaste, providing consistency and stability.

- Industrial Applications: In industrial applications, MCC serves as a filler, binder, and flow aid in products like paints, coatings, adhesives, and sealants. Its stability and uniform particle size make it ideal for these purposes.

- Pharmaceutical Coating: MCC is used as a coating agent in pharmaceuticals to control the release of active ingredients, enhancing the stability and shelf-life of drugs.

- Animal Feed: In animal nutrition, MCC is added as a fiber supplement, offering nutritional benefits and improving the physical texture of feed pellets.

- 3D Printing and Filament Manufacturing: MCC is increasingly being used in the production of bio-based 3D printing filaments. It provides stability, binding, and structural integrity to the final product.

- Dietary Supplements: It is widely used in dietary supplements as a bulking agent and to enhance the bioavailability of nutrients in tablet and capsule forms.

- Paper Industry: In papermaking, MCC is used as a filler to enhance the physical properties and quality of paper products, providing improved texture, opacity, and brightness.

- Medical Devices: MCC is also used in the production of certain medical devices, such as wound care products and absorbent pads, where it provides stability, absorbency, and non-reactivity.