Vinyl Versatate

Product Description

Vinyl Versatate, also known as vinyl neodecanoate, is a versatile monomer that finds various industrial applications due to its unique properties like hydrophobicity and flexibility.

Product:

Vinyl Versatate

CAS:

51000-52-3

Synonym:

Vinyl neodecanoate; Neodecanoic acid vinyl ester; Ethenyl 7,7-dimethyloctanoate

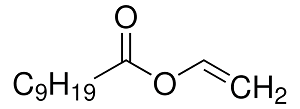

Structure:

Typical Characteristics

Appearance

Clear, colorless liquid

Boiling point

60-216 °C

Density

0.882 g/cm3

Flash Point

85 °C

Molecular Weight

198.30

Odor

Pleasant odor

Purity

99%

Refractive index

1.436

Uses, Applications & Markets

Key applications

get a quote

We Offer Vinyl Versatate

in various grades

A few of the grades available are listed below:

Vinyl Versatate used in many

industry applications

Vinyl Versatate, also known as vinyl neodecanoate, is a versatile monomer that finds various industrial applications due to its unique properties like hydrophobicity and flexibility. Below are some of the key applications of Vinyl Versatate:

- Paints and Coatings: Vinyl Versatate is widely used in the formulation of paints and coatings, particularly in emulsion systems. It provides improved water resistance, flexibility, and adhesion properties, making it suitable for both interior and exterior applications.

- Adhesives and Sealants: It is used as a monomer in the production of pressure-sensitive adhesives (PSAs) and sealants, contributing to better adhesive strength and durability under various environmental conditions.

- Textile and Leather Finishing: In the textile and leather industry, Vinyl Versatate is used in finishing agents to enhance the water and chemical resistance of fabrics and leather, as well as to provide a soft, flexible feel.

- Polymer Modification: Vinyl Versatate is often copolymerized with other monomers such as vinyl acetate, acrylics, or styrene to modify the properties of polymers. This enhances flexibility, weather resistance, and toughness of the resulting materials.

- Construction Materials: It is used in construction materials such as waterproofing membranes, caulks, and sealants to provide long-lasting flexibility and resistance to environmental degradation.

- Automotive Industry: Vinyl Versatate-based polymers are used in automotive coatings and adhesives for their resistance to chemicals, weathering, and mechanical wear, ensuring durability and a long-lasting finish.