Fumed Silica

Product Description

Fumed silica, also known as silica fume or pyrogenic silica, finds wide-ranging industrial applications due to its unique properties.

Product:

Fumed Silica

CAS:

112945-52-5

Synonym:

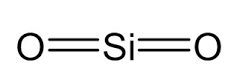

Pyrogenic silica; Silica; Silicic anhydride; Silicon dioxide; Silicon dioxide amorphous

Structure:

Typical Characteristics

Appearance

Transparent to gray powder

Boiling point

2230 °C

Density

2.3-4.5 g/cm3

Melting point

1600 °C

Molecular Weight

60.08

Odor

Odorless

Purity

99.8%

Refractive index

1.46

Uses, Applications & Markets

Key applications

get a quote

We Offer Fumed Silica

in various grades

A few of the grades available are listed below:

Fumed Silica used in many

industry applications

Fumed silica, also known as silica fume or pyrogenic silica, is a fine, white powder composed of amorphous silicon dioxide (SiO2) particles. It is produced through the high-temperature hydrolysis of silicon tetrachloride or silicon compounds in a flame or plasma reactor. Fumed silica finds wide-ranging industrial applications due to its unique properties, including:

- Thickening and Thixotropy: Fumed silica is commonly used as a thickening and thixotropic agent in various liquid systems such as paints, coatings, adhesives, and sealants. It imparts viscosity control, prevents sagging or dripping, and improves the stability and application properties of these formulations.

- Reinforcement and Rheology Modification: In rubber and elastomer compounds, fumed silica acts as a reinforcing filler, enhancing mechanical properties such as tensile strength, tear resistance, and abrasion resistance. It also functions as a rheology modifier, adjusting the flow behavior and processing characteristics of rubber formulations.

- Matting and Surface Modification: Fumed silica is employed as a matting agent and surface modifier in paints, coatings, plastics, and cosmetics. It creates a matte or satin finish, improves scratch resistance, and enhances the surface smoothness, texture, and slip resistance of finished products.

- Anti-Blocking and Anti-Caking: Due to its high surface area and porosity, fumed silica serves as an effective anti-blocking and anti-caking agent in powdered and granular materials. It prevents the agglomeration or sticking together of particles, ensuring free-flowing and pourable characteristics in powders and granules.

- Thermal Insulation: Fumed silica exhibits excellent thermal insulating properties, making it suitable for use in thermal insulation materials, fire-resistant coatings, and passive fire protection systems. It minimizes heat transfer, improves energy efficiency, and enhances the fire performance of building materials.

- Matte Polishing and Defoaming: In the manufacturing of ceramics, glass, and metal surfaces, fumed silica is employed for matte polishing and as a defoaming agent. It imparts a uniform matte finish to glassware and metal products while reducing surface defects and bubble formation during processing.