HI! I’M ELEMENT AI.

Tetrachlorophthalic Anhydride

Product Description

Tetrachlorophthalic anhydride is a cyclic dicarboxylic anhydride chemical compound with various industrial applications.

Product:

Tetrachlorophthalic Anhydride

CAS:

117-08-8

Synonym:

1,3-Dioxy-4,5,6,7-tetrachloroisobenzofuran; 4,5,6,7-Tetrachloro-1,3-isobenzofurandione

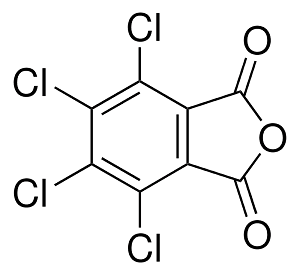

Structure:

Typical Characteristics

Appearance

White powder

Boiling point

371 °C

Density

1.49 g/cm3

Flash Point

362 °C

Melting point

253-257 °C

Molecular Weight

285.90

Odor

Odorless

Purity

96%

Refractive index

1.656

Uses, Applications & Markets

Key applications

get a quote

We Offer Tetrachlorophthalic Anhydride

in various grades

A few of the grades available are listed below:

Tetrachlorophthalic Anhydride used in many

industry applications

Tetrachlorophthalic anhydride is a cyclic dicarboxylic anhydride chemical compound with various industrial applications. Here are some of its main uses:

- Intermediate in Chemical Synthesis: Tetrachlorophthalic anhydride serves as an important intermediate in the synthesis of various organic compounds, including dyes, pigments, pharmaceuticals, and agrochemicals. It undergoes reactions with a wide range of reagents to produce functionalized derivatives used in diverse industrial processes.

- Manufacture of Flame Retardants: It is utilized in the production of flame retardants for plastics, textiles, and other materials. Tetrachlorophthalic anhydride-based flame retardants are incorporated into polymer formulations to enhance their fire resistance and reduce the risk of ignition and spread of flames, making them suitable for applications requiring stringent fire safety standards.

- Epoxy Resin Curing Agent: Tetrachlorophthalic anhydride is employed as a curing agent or hardener for epoxy resins in the formulation of high-performance coatings, adhesives, and composites. It reacts with epoxy groups in the resin matrix to form crosslinked networks, imparting strength, durability, and chemical resistance to epoxy-based materials.

- Corrosion Inhibitor: It finds applications as a corrosion inhibitor in metalworking fluids, lubricants, and rust preventives to protect metal surfaces from degradation caused by exposure to corrosive environments. Tetrachlorophthalic anhydride-based corrosion inhibitors form protective films on metal surfaces, reducing the rate of corrosion and extending the service life of equipment and machinery.

- Textile Auxiliary: It is used in the textile industry as a dye auxiliary agent and flame retardant for synthetic fibers and fabrics. Tetrachlorophthalic anhydride can improve the color fastness and wash resistance of dyed textiles and impart flame retardant properties to enhance their safety and compliance with fire safety regulations.

- Photographic Chemicals: This compound is employed in the formulation of photographic developers and fixers. It serves as a developing agent in black-and-white film processing, facilitating the reduction of silver halide crystals to metallic silver. Moreover, tetrachlorophthalic anhydride is employed as a fixing agent to remove unexposed silver halide grains from photographic emulsions, thereby stabilizing the developed image and preventing further light-induced reactions.

- Adhesive Formulation: Tetrachlorophthalic anhydride is used in the formulation of structural adhesives and sealants for bonding a wide range of substrates, including metals, plastics, ceramics, and composites. It serves as a curing agent or crosslinker in epoxy and polyurethane adhesives, providing strong and durable bonds with excellent adhesion and chemical resistance.

- Wood Preservation: It is employed in the preservation of wood and wood-based products against fungal decay and insect attack. Tetrachlorophthalic anhydride can penetrate the wood structure and inhibit the growth of wood-rotting fungi and wood-boring insects, prolonging the service life of treated wood in outdoor and damp environments.

- Plasticizer: In some applications, tetrachlorophthalic anhydride is used as a plasticizer for polyvinyl chloride (PVC) and other polymers to improve their flexibility, processability, and mechanical properties. It acts as a softening agent, reducing the brittleness of plastics and enhancing their suitability for molding, extrusion, and other processing techniques.