Synthetic Cryolite

Product Description

Synthetic Cryolite is a chemical compound with various industrial applications, primarily in the aluminum production and other specialized areas. Its unique properties make it valuable in several fields.

Product:

Synthetic Cryolite

CAS:

15096-52-3

Synonym:

Sodium aluminum fluoride; Sodium fluoroaluminate; Sodium hexafluoroaluminate; Trisodium hexafluoroaluminate

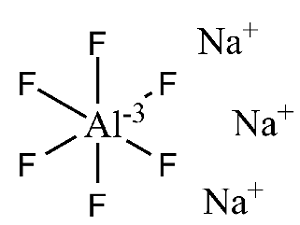

Structure:

Typical Characteristics

Appearance

Colorless, crystalline solid

Density

2.9 g/cm3

Melting point

1012 °C

Molecular Weight

209.94

Odor

Odorless

Purity

99.5%

Refractive index

1.338

Uses, Applications & Markets

Key applications

Markets

get a quote

We Offer Synthetic Cryolite

in various grades

A few of the grades available are listed below:

Synthetic Cryolite used in many

industry applications

Synthetic Cryolite is a chemical compound with various industrial applications, primarily in the aluminum production and other specialized areas. Its unique properties make it valuable in several fields. Here are some of its key industrial uses:

- Aluminum Production: Synthetic Cryolite is predominantly used as a flux in the electrolytic reduction of alumina to aluminum. It helps lower the melting point of the alumina and improves the efficiency of the electrolysis process in the Hall-Héroult process.

- Glass Manufacturing: In the glass industry, Synthetic Cryolite is used as a flux to lower the melting temperature of raw materials and improve the quality of the glass. It aids in the production of specialty glasses with enhanced properties.

- Metal Processing: The compound is employed in the processing of various metals, including in the production of certain alloys and in metallurgical operations. It helps improve the quality and performance of metal products.

- Mining Industry: Synthetic Cryolite is used in the mining industry for certain mineral processing applications. It helps in the separation and concentration of valuable minerals from ores.

- Ceramics: In the ceramics industry, Synthetic Cryolite is used as a flux to lower the firing temperature of ceramic materials. This results in better energy efficiency and improved properties of the final ceramic products.

- Research and Development: The compound is used in research and development for studying its properties and exploring new applications. Researchers investigate its potential uses in various industrial processes and formulations.