HI! I’M ELEMENT AI.

Trimethylolpropane Triacrylate

Product Description

Trimethylolpropane triacrylate is a multifunctional monomer with a wide range of industrial applications.

Product:

Trimethylolpropane Triacrylate

CAS:

15625-89-5

Synonym:

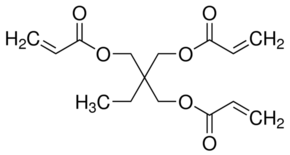

TMPTA; 2,2-bis(prop-2-enoyloxymethyl)butyl prop-2-enoate

Structure:

Typical Characteristics

Appearance

Colorless to Yellow Viscous Liquid

Boiling point

> 200 °C

Density

1.1 g/cm3

Flash Point

> 110 ºC

Melting point

- 66 °C

Molecular Weight

296.32

Odor

Acrylic or pungent odor

Purity

99.0 %

Refractive index

1.474

Uses, Applications & Markets

Key applications

get a quote

We Offer Trimethylolpropane Triacrylate

in various grades

A few of the grades available are listed below:

Trimethylolpropane Triacrylate used in many

industry applications

Trimethylolpropane triacrylate (TMPTA) is a versatile compound with various industrial applications. Here's a list of some of its uses:

- UV-Curable Coatings: TMPTA is widely used as a crosslinking agent and monomer in UV-curable coatings, inks, and adhesives. It polymerizes rapidly upon exposure to ultraviolet light, forming durable and chemically resistant coatings.

- Adhesives: It serves as a crosslinking agent in the formulation of UV-curable adhesives for bonding substrates such as glass, metal, plastics, and wood. The resulting adhesive bonds exhibit high strength and excellent adhesion properties.

- 3D Printing: TMPTA is utilized as a monomer in the formulation of UV-curable resins for stereolithography (SLA) and digital light processing (DLP) 3D printing technologies. It enables the rapid polymerization of resins layer by layer, producing high-resolution 3D printed objects.

- Coatings and Inks: It is employed in the formulation of UV-curable coatings and inks for various applications, including packaging, labeling, signage, and electronics. TMPTA-based coatings and inks offer fast curing, excellent adhesion, and enhanced surface properties.

- Optical Materials: TMPTA is used in the production of optical materials, such as lenses, optical fibers, and light guides, where it serves as a matrix resin in UV-curable formulations. The resulting materials exhibit high transparency and optical clarity.

- Encapsulation: It is utilized in the encapsulation of electronic components, photovoltaic cells, and microelectromechanical systems (MEMS) for protection against moisture, mechanical stress, and environmental degradation. TMPTA-based encapsulants offer high reliability and long-term stability.

- Surface Modification: TMPTA is employed in surface modification processes, such as plasma treatment and graft polymerization, to introduce functional groups onto substrates for improved adhesion, wetting, and compatibility with coatings and adhesives.

- Biomedical Applications: It finds use in biomedical applications, such as dental materials, medical adhesives, and tissue engineering scaffolds, where it serves as a crosslinking agent in UV-curable formulations. TMPTA-based materials exhibit biocompatibility and sterilizability.

- Printed Circuit Boards (PCBs): TMPTA is used in the production of UV-curable solder masks and conformal coatings for protecting and insulating PCBs. These coatings offer excellent electrical insulation, chemical resistance, and thermal stability.

- Automotive Coatings: It is employed in the formulation of UV-curable coatings for automotive refinishing and OEM applications. TMPTA-based coatings provide high gloss, scratch resistance, and weatherability, meeting stringent automotive industry requirements.