HI! I’M ELEMENT AI.

Dibromoneopentyl Glycol

Product Description

Dibromoneopentyl glycol is utilized in several industrial applications.

Product:

Dibromoneopentyl Glycol

CAS:

3296-90-0

Synonym:

2,2-Bis(bromomethyl)-1,3-propanediol; 1,3-Dibromo-2,2-bis(hydroxymethyl)propane; Dibromoneopentyl glycol; Pentaerythritol dibromide; Pentaerythritol dibromohydrin

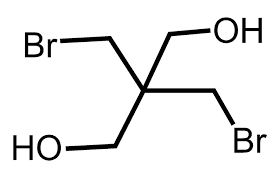

Structure:

Typical Characteristics

Appearance

White to off-white solid

Boiling point

235 °C

Density

1.8049 g/m3

Melting point

112-114 °C

Molecular Weight

261.94

Purity

98%

Refractive index

1.5120

Uses, Applications & Markets

Key applications

get a quote

We Offer Dibromoneopentyl Glycol

in various grades

A few of the grades available are listed below:

Dibromoneopentyl Glycol used in many

industry applications

Dibromoneopentyl glycol is utilized in several industrial applications. Here are some of its primary uses:

- Flame Retardants: Dibromoneopentyl glycol is used as a flame retardant additive in various materials such as plastics, textiles, and coatings. It works by releasing bromine radicals when exposed to heat or flame, which interfere with the combustion process, thus reducing the flammability and slowing down the spread of fire.

- Polymer Additive: It serves as a reactive monomer or crosslinking agent in the synthesis of flame-retardant polymers and resins. By incorporating dibromoneopentyl glycol into polymer matrices, it enhances the fire resistance and thermal stability of the resulting materials, making them suitable for applications in construction, electronics, and transportation.

- UV Stabilizers: Dibromoneopentyl glycol is utilized as a UV stabilizer in plastics and coatings to protect against degradation caused by exposure to ultraviolet (UV) radiation. It absorbs UV light and dissipates the absorbed energy as heat, thereby preventing the degradation of polymers and extending the service life of UV-sensitive materials.

- Electrical Insulation: It is employed in the production of electrical insulating materials such as wires, cables, and electrical enclosures. Dibromoneopentyl glycol enhances the fire resistance and electrical performance of insulating polymers, ensuring the safety and reliability of electrical systems in various applications.

- Textile Finishing: Dibromoneopentyl glycol-based formulations are used as flame-retardant coatings or finishes for textiles, carpets, and upholstery fabrics. They impart flame resistance to textile materials without compromising their softness, flexibility, or appearance, making them suitable for use in residential, commercial, and industrial settings.

- Adhesives and Sealants: It serves as a flame-retardant additive in adhesive and sealant formulations for construction, automotive, and aerospace applications. Dibromoneopentyl glycol improves the fire performance and durability of bonded joints, sealant seams, and structural adhesives, meeting stringent safety and regulatory requirements.

- Thermal Plastics: Dibromoneopentyl glycol is incorporated into thermoplastic polymers such as polyethylene, polypropylene, and polystyrene to impart flame retardancy and heat resistance. It facilitates the formation of char layers during combustion, which act as insulating barriers and inhibit the spread of flames, smoke, and toxic gases.

- Construction Materials: It is used in the production of flame-retardant building materials such as insulation foams, roofing membranes, and structural composites. Dibromoneopentyl glycol enhances the fire safety and performance of construction products, contributing to the protection of buildings and occupants against fire hazards.