HI! I’M ELEMENT AI.

Vinyl Neodecanoate

Product Description

Vinyl neodecanoate is a chemical compound with various industrial applications.

Product:

Vinyl Neodecanoate

CAS:

51000-52-3

Synonym:

Neodecanoic acid, vinyl ester; Vinyl tert-decanoate

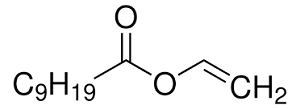

Structure:

Typical Characteristics

Appearance

Colorless liquid

Boiling point

60-216 °C

Density

0.882 g/cm3

Flash Point

83 °C

Melting point

-20 °C

Molecular Weight

198.30

Odor

Pleasant odor

Purity

99%

Refractive index

1.436

Uses, Applications & Markets

Key applications

get a quote

We Offer Vinyl Neodecanoate

in various grades

A few of the grades available are listed below:

Vinyl Neodecanoate used in many

industry applications

Vinyl neodecanoate is a chemical compound with various industrial applications. Here are some of its main uses:

- Paints and Coatings: Vinyl neodecanoate is commonly used as a monomer in the production of acrylic and vinyl-based paints and coatings. It contributes to the formation of polymer networks with excellent adhesion, weather resistance, and durability properties. Paints and coatings containing vinyl neodecanoate exhibit enhanced flexibility, UV resistance, and chemical resistance, making them suitable for outdoor applications, automotive finishes, and industrial coatings.

- Adhesives and Sealants: It serves as a reactive monomer in the formulation of adhesives and sealants, particularly those based on acrylic and vinyl chemistry. Vinyl neodecanoate helps improve the bond strength, cohesion, and flexibility of adhesive formulations, enabling them to bond to a wide range of substrates, including metals, plastics, and composites. It also enhances the water resistance and weatherability of adhesives and sealants, making them suitable for outdoor and high-humidity environments.

- Emulsion Polymers: Vinyl neodecanoate is used in the production of emulsion polymers for various applications, such as paper coatings, textiles, and construction materials. It serves as a reactive comonomer in emulsion polymerization processes, leading to the formation of latex particles with controlled particle size, morphology, and polymer composition. Emulsion polymers containing vinyl neodecanoate exhibit excellent film-forming properties, adhesion, and water resistance, making them ideal for use in coatings, adhesives, and sealants.

- Textile Treatments: It is utilized as a finishing agent in textile treatments to impart water repellency, stain resistance, and wrinkle resistance to fabrics. Vinyl neodecanoate-based coatings form a protective barrier on textile surfaces, preventing the penetration of water, oil, and other contaminants. Treated textiles exhibit improved durability, soil release properties, and ease of care, making them suitable for use in apparel, outdoor gear, and home furnishings.

- Paper Coatings: Vinyl neodecanoate is employed as a coating additive in the production of paper and paperboard products. It enhances the surface properties of paper substrates, such as smoothness, printability, and water resistance. Coated papers containing vinyl neodecanoate exhibit improved ink adhesion, color vibrancy, and resistance to smudging and feathering, making them suitable for high-quality printing applications, including magazines, catalogs, and packaging materials.

- Construction Materials: Vinyl neodecanoate is used in the formulation of construction materials, such as architectural coatings, sealants, and waterproofing membranes. It contributes to the development of coatings and sealants with excellent weather resistance, adhesion, and flexibility properties. Construction materials containing vinyl neodecanoate provide long-lasting protection against moisture intrusion, UV degradation, and environmental contaminants, enhancing the durability and performance of building structures.

- Personal Care Products: It is employed as a monomer in the production of personal care products, including hair styling products, nail polishes, and cosmetics. Vinyl neodecanoate-based polymers help improve the texture, film-forming properties, and water resistance of cosmetic formulations. They also enhance the longevity and wearability of personal care products, ensuring long-lasting performance and appearance on the skin or hair.

- Plastic Additives: Vinyl neodecanoate can be used as an additive in the production of plastic materials to improve their flexibility, impact resistance, and weatherability. It acts as a comonomer in the polymerization of vinyl polymers, resulting in plastics with enhanced mechanical properties and thermal stability. Plastic products containing vinyl neodecanoate are used in various applications, including automotive parts, electrical enclosures, and outdoor equipment.