HI! I’M ELEMENT AI.

Alkyl Melamine Formaldehyde

Product Description

Alkyl melamine formaldehyde is a chemical compound with various industrial applications, primarily in the adhesives and coatings industries

Product:

Alkyl Melamine Formaldehyde

CAS:

68036-97-5

Synonym:

1,3,5-Triazine-2,4,6-triamine, polymer with formaldehyde, butylated methylated

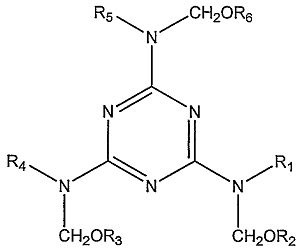

Structure:

Typical Characteristics

Appearance

Clear or slightly yellowish liquid or solid resin

Density

1.096 g/cm3

Melting point

>330 °C

Refractive index

1.50

Uses, Applications & Markets

Key applications

get a quote

We Offer Alkyl Melamine Formaldehyde

in various grades

A few of the grades available are listed below:

Alkyl Melamine Formaldehyde used in many

industry applications

Alkyl melamine formaldehyde is a chemical compound with various industrial applications, primarily in the adhesives and coatings industries. Here are some of its uses:

- Adhesives: Alkyl melamine formaldehyde resins are commonly used as crosslinkers in adhesive formulations, particularly in wood adhesives, laminating adhesives, and paperboard adhesives. They provide excellent bonding strength, heat resistance, and water resistance.

- Coatings: These resins are employed as film-forming agents and crosslinkers in coatings and paints, especially in automotive coatings, coil coatings, and industrial coatings. They enhance the durability, scratch resistance, and chemical resistance of coatings.

- Textile Treatments: Alkyl melamine formaldehyde resins are sometimes used in the textile industry as finishing agents to improve the crease resistance, wrinkle resistance, and dimensional stability of fabrics.

- Paper Industry: They are used as wet-strength additives and paper modifiers in the papermaking process to enhance the strength, stiffness, and dimensional stability of paper and paperboard products.

- Molding Compounds: Alkyl melamine formaldehyde resins are utilized in the production of molding compounds, such as melamine formaldehyde molding powders and melamine formaldehyde foams, for molding and shaping thermosetting plastics.

- Foundry Binders: They can be used as binders in foundry sand cores and molds to improve their strength, dimensional accuracy, and resistance to high temperatures during metal casting processes.