Diethyltoluenediamine

Product Description

Diethyltoluenediamine (DETDA), a curing agent and chain extender commonly used in the production of polyurethane elastomers and coatings, possesses several industrial applications.

Product:

Diethyltoluenediamine

CAS:

68479-98-1

Synonym:

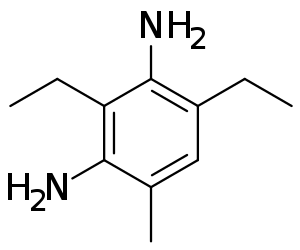

2,4-diethyl-5-methylbenzene-1,3-diamine

Structure:

Typical Characteristics

Appearance

Light yellow to amber transparent liquid

Boiling point

310 °C

Density

1.022 g/cm3

Flash Point

>140 °C

Molecular Weight

178.28

Odor

Slight amine odor

Purity

98%

Refractive index

1.581

Uses, Applications & Markets

Key applications

get a quote

We Offer Diethyltoluenediamine

in various grades

A few of the grades available are listed below:

Diethyltoluenediamine used in many

industry applications

Diethyltoluenediamine (DETDA), a curing agent and chain extender commonly used in the production of polyurethane elastomers and coatings, possesses several industrial applications:

- Polyurethane Elastomers: DETDA is a crucial component in the formulation of polyurethane elastomers, where it serves as a curing agent to crosslink polyols and isocyanates, resulting in the formation of durable and resilient elastomeric materials. These elastomers find applications in various industries, including automotive, footwear, construction, and industrial manufacturing.

- Coatings and Adhesives: It is employed as a curing agent and crosslinking agent in polyurethane coatings and adhesives to enhance their mechanical properties, chemical resistance, and durability. These coatings are used in automotive finishes, industrial coatings, flooring systems, and structural adhesives.

- Sealants and Potting Compounds: DETDA is utilized in the formulation of polyurethane sealants and potting compounds for sealing joints, bonding substrates, and encapsulating electronic components. These materials provide excellent adhesion, flexibility, and resistance to environmental factors.

- Cast Elastomers: It is used in the production of cast polyurethane elastomers for applications requiring high abrasion resistance, tear strength, and load-bearing capacity, such as conveyor belts, rollers, gaskets, and industrial parts.

- Structural Foams: DETDA can be incorporated into polyurethane foams to produce rigid and semi-rigid structural foams used in insulation panels, composite cores, and lightweight construction materials, offering thermal insulation and structural support.

- Molding and Tooling: It is employed in the manufacturing of molds, tooling, and prototypes using polyurethane casting and molding processes, allowing for the production of complex shapes and customized parts with precise dimensions and surface finishes.

- Textile Coatings: DETDA-containing polyurethane coatings are applied to textiles and fabrics to impart water repellency, abrasion resistance, and durability, enhancing their performance in outdoor apparel, upholstery, and industrial textiles.

- Corrosion Protection: Polyurethane coatings formulated with DETDA serve as protective coatings for metal substrates, providing corrosion resistance and weatherability in marine, automotive, and infrastructure applications.