HI! I’M ELEMENT AI.

Diethylene Glycol Dibenzoate

Product Description

Diethylene glycol dibenzoate is a chemical compound with various industrial applications.

Product:

Diethylene Glycol Dibenzoate

CAS:

120-55-8

Synonym:

2-(2-benzoyloxyethoxy)ethyl benzoate; Diglycol dibenzoate; Dibenzoyldiethyleneglycol ester

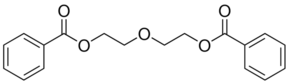

Structure:

Typical Characteristics

Appearance

Clear Liquid

Density

1.175 g/cm3

Flash Point

232 °C

Melting point

-28 °C

Molecular Weight

314.33

Odor

Mild ester odor

Purity

90 %

Refractive index

1.544

Uses, Applications & Markets

Key applications

get a quote

We Offer Diethylene Glycol Dibenzoate

in various grades

A few of the grades available are listed below:

Diethylene Glycol Dibenzoate used in many

industry applications

Diethylene glycol dibenzoate is a chemical compound with various industrial applications. Here's a list of some of its uses:

- Plastics Industry: Diethylene glycol dibenzoate is commonly used as a plasticizer in the production of thermoplastic polymers, such as polyvinyl chloride (PVC), polyethylene terephthalate (PET), and polypropylene (PP). It helps improve the flexibility, durability, and processability of plastic materials, making them suitable for a wide range of applications, including packaging, construction, and automotive components.

- Adhesives and Sealants: It is used as a plasticizer and tackifier in the formulation of adhesives, sealants, and caulks. Diethylene glycol dibenzoate helps improve adhesion, cohesion, and flexibility in adhesive formulations, making them suitable for bonding a variety of substrates, including wood, metal, plastics, and ceramics.

- Coatings and Paints: Diethylene glycol dibenzoate is used as a plasticizer and film-forming agent in coatings and paints. It helps improve the flexibility, adhesion, and weather resistance of coating formulations, allowing them to adhere well to substrates and withstand exposure to harsh environmental conditions.

- Resins and Composites: It is used as a reactive diluent and modifier in the production of thermosetting resins and composite materials. Diethylene glycol dibenzoate can be incorporated into epoxy, polyester, and urethane resins to reduce viscosity, improve flow properties, and enhance mechanical properties in cured composites.

- Printing Inks: Diethylene glycol dibenzoate is used as a plasticizer and solvent in the formulation of printing inks, including flexographic, gravure, and screen printing inks. It helps improve ink flow, printability, and adhesion to substrates, resulting in high-quality prints with vibrant colors and sharp details.

- Personal Care Products: It is used in the formulation of personal care products, including cosmetics, skincare products, and hair care products. Diethylene glycol dibenzoate serves as a solvent, emollient, and viscosity regulator, helping to improve product texture, spreadability, and stability.

- Textile Auxiliaries: Diethylene glycol dibenzoate is used in textile processing as a softening agent and lubricant for natural and synthetic fibers. It helps to improve fabric softness, hand feel, and dye uptake during the dyeing and finishing processes, resulting in textiles with enhanced comfort and appearance.

- Industrial Cleaners: It is used as a solvent and coupling agent in industrial cleaning formulations, such as degreasers, solvent cleaners, and metalworking fluids. Diethylene glycol dibenzoate helps dissolve and remove oil, grease, and other contaminants from surfaces, facilitating cleaning and maintenance operations.

- Adjuvants in Agriculture: Diethylene glycol dibenzoate is used as an adjuvant or inert ingredient in agricultural formulations, such as herbicides, insecticides, and fungicides. It helps improve the stability, dispersion, and efficacy of active ingredients in pesticide formulations, enhancing their performance and safety during application.

- Electronics Industry: Diethylene glycol dibenzoate is used as a plasticizer and solvent in the production of electronic components, such as cables, wires, and circuit boards. It helps improve the flexibility and durability of plastic materials used in electronic devices, as well as facilitate the manufacturing process.