Sodium Silicate

Product Description

Sodium silicate, also known as water glass or liquid glass, is a chemical compound with various industrial applications.

Product:

Sodium Silicate

CAS:

1344-09-8

Synonym:

Sodium metasilicate; Water glass; Liquid glass

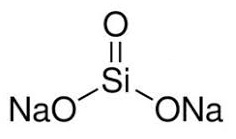

Structure:

Typical Characteristics

Appearance

Colorless, white, or translucent solid

Density

2.6 g/cm3

Melting point

1089 °C

Molecular Weight

122.06

Odor

Odorless

Purity

99%

Refractive index

1.520

Uses, Applications & Markets

Key applications

get a quote

We Offer Sodium Silicate

in various grades

A few of the grades available are listed below:

Sodium Silicate used in many

industry applications

Sodium silicate, also known as water glass or liquid glass, is a chemical compound with various industrial applications. Here are some of its main uses:

- Adhesive Binder: Sodium silicate is commonly used as an adhesive binder in the manufacturing of cardboard, paperboard, and paper products. It acts as a binding agent that holds cellulose fibers together, improving the strength, stiffness, and durability of the final paper-based materials. Sodium silicate-based adhesives are also utilized in the production of corrugated cardboard boxes, paper tubes, and laminated paper products.

- Detergent Builder: Sodium silicate is employed as a detergent builder or water softener in laundry detergents, automatic dishwashing detergents, and industrial cleaning products. It helps remove mineral deposits and hard water stains by binding to calcium and magnesium ions, preventing them from interfering with the cleaning process. Sodium silicate-based detergents enhance the cleaning efficiency and performance of laundry and dishwashing machines.

- Concrete and Cement Additive: Sodium silicate is used as an additive in concrete and cement formulations to improve their performance and properties. It acts as a cement accelerator, reducing the setting time and increasing the early strength development of concrete mixtures. Sodium silicate also functions as a concrete sealer and waterproofing agent, enhancing the durability and resistance of concrete structures to moisture penetration, chemical attack, and abrasion.

- Soil Stabilization: Sodium silicate is utilized in soil stabilization applications to improve the engineering properties of soils and aggregates. It reacts with clay minerals and fine particles in the soil to form stable compounds, reducing soil swelling, erosion, and dust formation. Sodium silicate-treated soils exhibit increased bearing capacity, reduced permeability, and enhanced compaction, making them suitable for road construction, embankment stabilization, and erosion control.

- Corrosion Inhibitor: Sodium silicate is employed as a corrosion inhibitor and rust converter in metal surface treatment applications. It forms a protective coating on metal surfaces, such as steel, iron, and aluminum, inhibiting the corrosion process and extending the service life of metal components. Sodium silicate-based coatings are used in automotive, marine, and industrial applications to protect metal structures, pipelines, storage tanks, and equipment from rust and corrosion.

- Fire Retardant: Sodium silicate is used as a fire retardant additive in various materials, including textiles, fabrics, wood, and building materials. It acts as a flame retardant by forming a heat-resistant intumescent layer when exposed to high temperatures. Sodium silicate-based fire retardants inhibit the spread of flames, reduce smoke emissions, and increase the fire resistance of combustible materials, improving their safety and compliance with fire regulations.

- Paper Sizing Agent: Sodium silicate is employed as a paper sizing agent in the papermaking industry to control the absorption and penetration of ink and liquids into paper fibers. It enhances the surface smoothness, printability, and ink holdout of paper products, resulting in improved print quality and color reproduction. Sodium silicate-based sizing agents are used in the production of printing papers, coated papers, and specialty papers for various printing and packaging applications.

- Textile Chemical: Sodium silicate is utilized as a textile chemical in textile processing and finishing operations. It functions as a wetting agent, sequestering agent, and dyeing auxiliary in textile dyeing, bleaching, and printing processes. Sodium silicate improves the wetting and penetration of dyes and chemicals into textile fibers, enhancing color fastness, dye uptake, and fabric softness. It is also used as a sizing agent in textile sizing formulations to add stiffness and body to yarns and fabrics.