Photoinitiator 754

Product Description

Photoinitiator 754, also known as 2,4,6-Trimethylbenzoyldiphenylphosphine oxide, is a versatile compound widely used in various industrial applications, particularly in photopolymerization processes.

Product:

Photoinitiator 754

CAS:

211510-16-6

Synonym:

2,4,6-Trimethylbenzoyldiphenylphosphine oxide; Benzeneacetic acid, alpha-oxo-, oxydi-2,1-ethanediyl ester; Irgacure 754

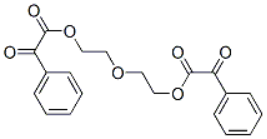

Structure:

Typical Characteristics

Appearance

Light yellow liquid

Boiling point

516 °C

Density

1.22 g/cm3

Melting point

<-22 °C

Molecular Weight

370.35

Purity

≥95%

Refractive index

1.540-1.545

Uses, Applications & Markets

Key applications

get a quote

We Offer Photoinitiator 754

in various grades

A few of the grades available are listed below:

Photoinitiator 754 used in many

industry applications

Photoinitiator 754, also known as 2,4,6-Trimethylbenzoyldiphenylphosphine oxide, is a versatile compound widely used in various industrial applications, particularly in photopolymerization processes. Here are some of its industrial uses:

- UV Curing: Photoinitiator 754 is commonly employed as a photoinitiator in UV-curable formulations, such as inks, coatings, adhesives, and dental materials. When exposed to ultraviolet (UV) light, it undergoes photolysis to generate free radicals or reactive species, initiating the polymerization or crosslinking of monomers and oligomers, leading to rapid curing and solidification of the material.

- 3D Printing: Photoinitiator 754 is utilized in UV-curable resins for stereolithography (SLA) and digital light processing (DLP) 3D printing technologies. It enables layer-by-layer photopolymerization of liquid resin into solid objects upon exposure to UV light, allowing for the rapid prototyping and manufacturing of intricate 3D structures with high resolution and accuracy.

- Coatings and Inks: Photoinitiator 754 is incorporated into UV-curable coatings and inks for various substrates, including wood, plastics, metals, and paper. It facilitates fast curing and drying of the coatings and inks upon UV exposure, resulting in durable and high-performance surface finishes with excellent adhesion, chemical resistance, and scratch resistance.

- Adhesives and Sealants: Photoinitiator 754 is used in UV-curable adhesives and sealants for bonding and sealing applications in industries such as electronics, automotive, and medical devices. It enables rapid bonding of substrates and assembly components upon exposure to UV light, leading to strong and durable bonds with minimal curing time and energy consumption.

- Optical Materials: Photoinitiator 754 is employed in the production of optical materials, such as lenses, optical fibers, and waveguides. It enables the fabrication of transparent and light-transmitting materials with precise dimensions and optical properties through photopolymerization processes, offering enhanced performance in optical communication and imaging systems.

- Dental Composites: Photoinitiator 754 is utilized in the formulation of dental composites for restorative and aesthetic dental procedures. It enables the rapid curing of composite resins used for dental fillings, crowns, bridges, and veneers upon exposure to dental curing lights, ensuring efficient and reliable dental treatments with excellent esthetics and mechanical properties.

- Electronic Materials: Photoinitiator 754 is incorporated into UV-curable formulations for electronic materials, such as printed circuit boards (PCBs), encapsulants, and coatings. It facilitates the rapid curing of electronic materials with precise patterning and dimensional control, leading to the production of high-performance electronic devices with improved reliability and longevity.

- Textile Printing: Photoinitiator 754 is used in UV-curable inks for textile printing applications, such as garment decoration, signage, and industrial textiles. It enables the rapid curing of inks on fabric substrates upon exposure to UV light, resulting in vibrant and durable prints with excellent color fastness and wash resistance.