Vinyl Toluene

Product Description

Vinyl toluene, also known as methylstyrene, is a versatile compound with various industrial applications.

Product:

Vinyl Toluene

CAS:

25013-15-4

Synonym:

Methylstyrene; 1-Methyl-3-vinylbenzene;

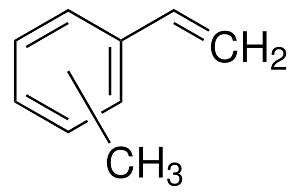

Structure:

Typical Characteristics

Appearance

Colorless liquid

Boiling point

168 °C

Density

0.893 g/cm3

Flash Point

51 °C

Melting point

-77 °C

Molecular Weight

118.18

Odor

Strong, disagreeable odor

Purity

99%

Refractive index

1.5425

Uses, Applications & Markets

Key applications

get a quote

We Offer Vinyl Toluene

in various grades

A few of the grades available are listed below:

Vinyl Toluene used in many

industry applications

Vinyl toluene, also known as methylstyrene, is a versatile compound with various industrial applications. Here are some of its uses:

- Monomer: Vinyl toluene serves as a monomer in the production of copolymers and polymer blends. It can be copolymerized with other vinyl monomers such as styrene, acrylics, and vinyl acetate to form resins with desirable properties such as flexibility, impact resistance, and adhesion. Vinyl toluene-based copolymers are used in coatings, adhesives, sealants, and synthetic rubbers.

- Coatings and Adhesives: Vinyl toluene-based resins are utilized in the formulation of coatings, paints, and adhesives for various applications. They provide excellent adhesion to substrates, fast drying times, and good chemical resistance. Vinyl toluene copolymers are used in architectural coatings, automotive finishes, industrial coatings, and specialty adhesives.

- Plasticizers: Vinyl toluene can be esterified to produce plasticizers for flexible PVC (polyvinyl chloride) and other polymer products. Vinyl toluene-based plasticizers improve the flexibility, elongation, and low-temperature performance of PVC compounds, making them suitable for applications such as wire and cable insulation, flooring, and medical devices.

- Resins and Emulsions: Vinyl toluene-based resins and emulsions are used in the manufacture of coatings, inks, and specialty chemicals. They can be formulated into water-based or solvent-based systems to provide specific performance properties such as adhesion, gloss, and durability. Vinyl toluene emulsions are used in paper coatings, textile finishes, and packaging adhesives.

- Printing Inks: Vinyl toluene-based resins are employed in the formulation of printing inks for various printing processes including offset, flexographic, gravure, and screen printing. They contribute to ink adhesion, color intensity, and printability on different substrates such as paper, cardboard, plastics, and metals. Vinyl toluene-based inks are used in packaging, publishing, labeling, and decorative printing.

- Rubber Modification: Vinyl toluene can be used as a modifier in the production of synthetic rubbers such as styrene-butadiene rubber (SBR) and acrylonitrile-butadiene rubber (NBR). It can improve the processability, mechanical properties, and aging resistance of rubber compounds. Vinyl toluene-modified rubbers are used in tire treads, conveyor belts, footwear, and industrial seals.

- Adhesive Tapes: Vinyl toluene-based adhesives are used in the manufacture of pressure-sensitive adhesive tapes and labels. They provide high tack, peel strength, and shear resistance for bonding to various substrates. Vinyl toluene adhesives are used in packaging tapes, masking tapes, double-sided tapes, and graphic films for signage and advertising.

- Composite Materials: Vinyl toluene-based resins are incorporated into composite materials for reinforcing fibers, fillers, and matrices. They enhance the adhesion between matrix and reinforcement, improve wet-out properties, and increase composite strength and stiffness. Vinyl toluene composites are used in aerospace, automotive, marine, and sporting goods applications.

- Textile Coatings: Vinyl toluene-based resins are used in textile coatings and finishes to impart water resistance, abrasion resistance, and durability to fabrics. They can be applied as coatings or laminates to enhance the performance and appearance of textiles in outdoor, industrial, and protective clothing applications.

- Specialty Chemicals: Vinyl toluene derivatives are used as intermediates in the synthesis of specialty chemicals such as fragrances, flavors, and pharmaceuticals. They can undergo various chemical reactions including halogenation, nitration, and sulfonation to produce functionalized compounds for diverse applications.