Tripropylene Glycol Monomethyl Ether

Product Description

Tripropylene glycol monomethyl ether is a low-volatility, non-flammable, colorless, clear liquid with an ether odor and an oily feel.

Product:

Tripropylene Glycol Monomethyl Ether

CAS:

25498-49-1

Synonym:

Tripropylene Glycol Methyl Ether; Methoxy Methyl Ethoxy; Methyl Ethoxy Propanol; Glycol Ether TPM

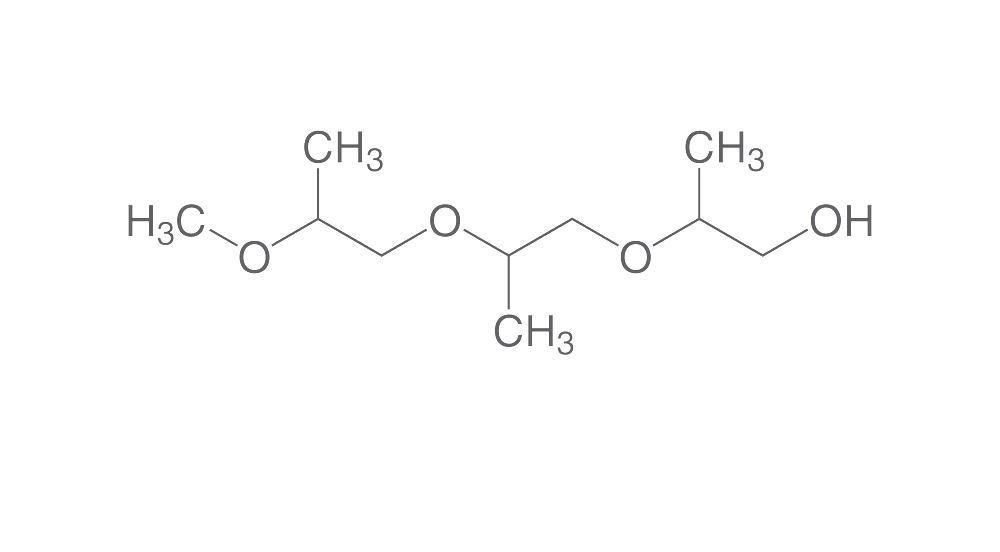

Structure:

Typical Characteristics

Appearance

Clear colorless liquid

Boiling point

243°C

Density

0.97 g/cm3

Flash Point

118°C

Melting point

-79°C

Molecular Weight

206.28

Odor

Mild odor

Purity

≥97.5 %

Refractive index

1.43

Uses, Applications & Markets

Key applications

get a quote

We Offer Tripropylene Glycol Monomethyl Ether

in various grades

A few of the grades available are listed below:

Tripropylene Glycol Monomethyl Ether used in many

industry applications

Tripropylene glycol monomethyl ether (TPM), a clear, colorless liquid with a mild odor, finds various industrial applications owing to its unique properties. Here's a list of some of its industrial uses:

- Paints and Coatings: Tripropylene glycol monomethyl ether is widely used as a solvent in paint and coating formulations, where it improves flow properties, film formation, and adhesion to substrates.

- Inks and Dyes: It serves as a solvent and dispersant in the formulation of printing inks, including flexographic, gravure, and screen printing inks, where it enhances ink flow, color dispersion, and print quality.

- Adhesives and Sealants: TPM is employed as a solvent and plasticizer in the formulation of adhesives, sealants, and caulks, where it improves flexibility, adhesion, and workability of the final product.

- Cleaners and Degreasers: It is used as a solvent in industrial cleaners and degreasers for the removal of oils, greases, and residues from metal surfaces, machinery, and equipment.

- Electronic Cleaners: TPM is utilized for precision cleaning of electronic components, printed circuit boards (PCBs), and semiconductor devices, where it removes flux residues, soldering residues, and other contaminants without leaving residues.

- Industrial Coatings: It is employed as a solvent in the formulation of industrial coatings, including automotive coatings, metal coatings, and wood finishes, where it improves application properties and coating performance.

- Surface Treatments: TPM is used as a solvent in surface treatments, such as metal cleaning, phosphating, and passivation processes, where it removes surface contaminants and promotes surface adhesion.

- Resin Manufacturing: It serves as a solvent and reactant in the production of resins, plasticizers, and specialty chemicals, where it contributes to the synthesis of polyester resins, polyurethanes, and epoxy resins.

- Textile Processing: TPM is employed in textile processing as a dyeing assistant and leveling agent to improve dye penetration, color uniformity, and fabric softness.

- Hydraulic Fluids: It is used as a component in hydraulic fluids and brake fluids to improve lubrication, viscosity, and thermal stability in hydraulic systems and brake mechanisms.

- Heat Transfer Fluids: TPM serves as a heat transfer fluid in HVAC systems, refrigeration units, and thermal storage systems, where it transfers heat efficiently due to its high thermal conductivity and low viscosity.

- Cosmetic Formulations: It is utilized in the production of cosmetics, such as skincare products, hair care products, and fragrances, as a solvent, emollient, and fragrance carrier.