HI! I’M ELEMENT AI.

Isobornyl Acrylate

Product Description

Isobornyl Acrylate, a monofunctional acrylic monomer, finds various industrial applications owing to its unique properties.

Product:

Isobornyl Acrylate

CAS:

5888-33-5

Synonym:

Acrylic acid isobornyl ester

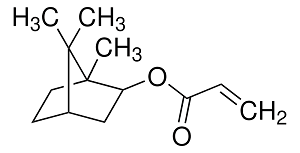

Structure:

Typical Characteristics

Appearance

Colorless liquid

Boiling point

119-121 °C/15 mmHg

Density

0.986 g/cm3

Flash Point

97 °C

Melting point

<-35°C

Molecular Weight

208.30

Purity

99%

Refractive index

1.476

Uses, Applications & Markets

Key applications

get a quote

We Offer Isobornyl Acrylate

in various grades

A few of the grades available are listed below:

Isobornyl Acrylate used in many

industry applications

Isobornyl Acrylate, a monofunctional acrylic monomer, finds various industrial applications owing to its unique properties. Here's a list of some of its industrial uses:

- UV/EB Curing: Isobornyl Acrylate is commonly used as a reactive diluent or co-monomer in ultraviolet (UV) and electron beam (EB) curable formulations. It enhances the flexibility, adhesion, and weatherability of UV/EB cured coatings, inks, adhesives, and sealants. Isobornyl Acrylate enables rapid curing, improved film formation, and reduced volatile organic compound (VOC) emissions in UV/EB curing processes.

- Pressure-Sensitive Adhesives: It is utilized as a key ingredient in the formulation of pressure-sensitive adhesives (PSAs) for tapes, labels, decals, and specialty films. Isobornyl Acrylate imparts tackiness, peel strength, shear resistance, and heat resistance to PSAs, making them suitable for various applications in packaging, automotive, construction, and electronics industries.

- Coatings and Inks: Isobornyl Acrylate serves as a versatile building block for the synthesis of high-performance coatings and inks for printing, packaging, textiles, and graphic arts. It offers excellent adhesion to diverse substrates, including plastics, metals, and paper, as well as good chemical resistance and mechanical properties. Isobornyl Acrylate-based coatings and inks exhibit low odor, low yellowing, and good UV resistance.

- Industrial Sealants: It is employed in the formulation of industrial sealants and caulks for construction, automotive, aerospace, and marine applications. Isobornyl Acrylate-based sealants provide superior adhesion, flexibility, and durability, enabling them to withstand extreme temperatures, weathering, and mechanical stress. They are used for bonding, sealing, and gap-filling in demanding environments.

- Plastic Additives: Isobornyl Acrylate is sometimes incorporated into thermoplastic and thermoset polymers as a reactive modifier or plasticizer to improve their processing characteristics and performance properties. It enhances the impact resistance, elongation at break, and dimensional stability of plastics, such as polyvinyl chloride (PVC), acrylics, and polyurethanes, without compromising other mechanical or thermal properties.

- Textile Finishes: Isobornyl Acrylate is used in the textile industry as a finishing agent or crosslinking agent for imparting wrinkle resistance, crease recovery, and water repellency to fabrics and garments. It enhances the durability, colorfastness, and comfort of textiles while reducing the need for ironing or dry cleaning. Isobornyl Acrylate-based textile finishes are applied by padding, spraying, or coating methods.

- Electronics Encapsulation: It is employed in the encapsulation of electronic components and assemblies to provide electrical insulation, moisture protection, and mechanical support. Isobornyl Acrylate-based encapsulants offer good adhesion to circuit boards, chips, and wires, as well as resistance to thermal cycling, humidity, and chemicals. They help extend the lifespan and reliability of electronic devices and systems.

- Photopolymer Resins: Isobornyl Acrylate is utilized in the formulation of photopolymer resins for stereolithography (SLA) and digital light processing (DLP) 3D printing applications. It serves as a reactive monomer or oligomer in UV-curable resin formulations, enabling the rapid prototyping and production of intricate, high-resolution parts with excellent surface finish and mechanical properties.

- Automotive Coatings: Isobornyl Acrylate is used in automotive coatings for vehicles, motorcycles, and industrial equipment to provide scratch resistance, gloss retention, and weathering performance. It contributes to the development of clearcoats, primers, and basecoats with improved hardness, adhesion, and resistance to abrasion, chemicals, and environmental degradation. Isobornyl Acrylate-based coatings help protect automotive surfaces and enhance their appearance and durability.

- Medical Devices: It is employed in the manufacture of medical devices and implants, such as catheters, tubing, and surgical instruments, as a biocompatible material with good sterilizability and dimensional stability. Isobornyl Acrylate-based polymers exhibit low toxicity, low extractables, and high purity, making them suitable for use in healthcare