Dipentaerythritol Pentaacrylate

Product Description

Dipentaerythritol pentaacrylate (DPPA) is a multifunctional acrylate monomer known for its high reactivity and versatility. It is widely used in various industries due to its excellent properties.

Product:

Dipentaerythritol Pentaacrylate

CAS:

60506-81-2

Synonym:

Dipentaerythritol penta-/hexa-acrylate; Dipentaerythritol monohydroxypentaacrylate

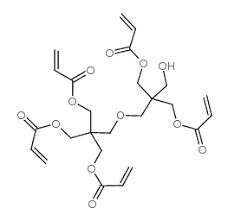

Structure:

Typical Characteristics

Appearance

Colorless to yellow liquid

Boiling point

619.6 °C

Density

1.155 g/cm3

Flash Point

197.2 °C

Molecular Weight

524.51

Purity

99%

Refractive index

1.49

Uses, Applications & Markets

Key applications

get a quote

We Offer Dipentaerythritol Pentaacrylate

in various grades

A few of the grades available are listed below:

Dipentaerythritol Pentaacrylate used in many

industry applications

Dipentaerythritol pentaacrylate (DPPA) is a multifunctional acrylate monomer known for its high reactivity and versatility. It is widely used in various industries due to its excellent properties. Here are some of its key industrial applications:

- UV-Curable Coatings: DPPA is extensively used in UV-curable coatings, providing rapid curing, high gloss, and excellent hardness for applications like wood finishes, automotive coatings, and industrial coatings.

- Adhesives: It is used in the formulation of high-performance adhesives, offering strong adhesion, fast curing, and resistance to environmental factors such as heat and moisture.

- Printing Inks: DPPA is used in UV-curable printing inks to enhance print quality, adhesion, and durability, particularly in applications requiring high-speed printing and quick drying.

- Electronics: It is used in the electronics industry for encapsulating and protecting electronic components, providing excellent electrical insulation and resistance to thermal and mechanical stress.

- Composite Materials: DPPA is used in composite materials to improve mechanical strength, thermal stability, and resistance to chemical and environmental degradation.

- Photopolymerization: It is employed in photopolymerization processes for the production of 3D printing resins, ensuring high resolution and fast curing times.

- Surface Coatings: DPPA is used in surface coatings to provide enhanced abrasion resistance, chemical resistance, and long-term durability for various substrates, including metals, plastics, and glass.

- Optical Materials: It is used in the production of optical materials, such as lenses and light guides, due to its high transparency and resistance to yellowing.

- Medical Devices: DPPA is used in the manufacturing of medical devices and dental materials, offering biocompatibility and resistance to sterilization processes.

- Packaging: It is used in packaging applications, particularly for creating barrier coatings that provide protection against moisture, oxygen, and other contaminants.