HI! I’M ELEMENT AI.

Hexahydrophthalic Anhydride

Product Description

Hexahydrophthalic anhydride (HHPA) is a cyclic anhydride compound widely used in various industrial applications.

Product:

Hexahydrophthalic Anhydride

CAS:

85-42-7

Synonym:

1,2-Cyclohexanedicarboxylic anhydride; Hexahydrophthalic acid anhydride

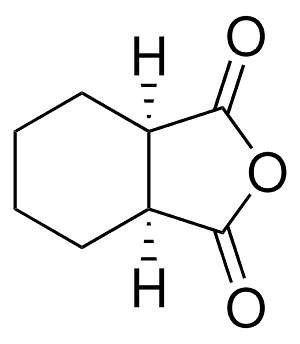

Structure:

Typical Characteristics

Appearance

White to Off-White solid

Boiling point

296 °C

Density

1.19 g/cm3

Flash Point

149 °C

Melting point

32-34 °C

Molecular Weight

154.16

Purity

95%

Refractive index

1.4620

Uses, Applications & Markets

Key applications

get a quote

We Offer Hexahydrophthalic Anhydride

in various grades

A few of the grades available are listed below:

Hexahydrophthalic Anhydride used in many

industry applications

Hexahydrophthalic anhydride (HHPA) is a cyclic anhydride compound widely used in various industrial applications. Here are some of its common uses:

- Epoxy Resins: HHPA is a key component in the production of epoxy resins, where it serves as a curing agent or hardener. It reacts with epoxy functional groups to form cross-linked polymer networks, imparting strength, durability, and chemical resistance to epoxy-based coatings, adhesives, and composites.

- Plasticizers: It is employed as a plasticizer or modifier in the formulation of synthetic polymers and thermosetting resins to improve flexibility, impact resistance, and processability. HHPA-based plasticizers find applications in PVC compounds, polyesters, polyurethanes, and other plastic materials.

- Alkyd Resins: HHPA is utilized in the synthesis of alkyd resins, which are widely used in the production of paints, coatings, and varnishes. It reacts with polyols and fatty acids to form polyester chains, providing film-forming properties, adhesion, and weatherability to alkyd-based coatings.

- Adhesives and Sealants: It is used as a curing agent or cross-linking agent in the formulation of adhesives, sealants, and encapsulants for bonding and sealing applications in construction, automotive, aerospace, and electronics industries. HHPA-based systems offer excellent adhesion, thermal stability, and chemical resistance.

- Surfactants: HHPA derivatives can be synthesized and used as surfactants or surface-active agents in various industrial and consumer products such as detergents, emulsifiers, wetting agents, and dispersants. They help reduce surface tension, enhance wetting, and stabilize emulsions and suspensions.

- Resin Modifiers: It is employed as a modifier or reactive diluent in the formulation of unsaturated polyester resins (UPRs) and vinyl ester resins (VERs) to adjust viscosity, cure kinetics, and mechanical properties. HHPA-based modifiers improve handling characteristics and compatibility with reinforcement materials in composite applications.

- Textile Chemicals: HHPA derivatives are used in textile finishing treatments as cross-linking agents or flame retardants for natural and synthetic fibers. They impart wrinkle resistance, crease recovery, and flame retardancy to textiles, carpets, and upholstery fabrics.

- Coating Additives: HHPA-based additives such as leveling agents, flow modifiers, and anti-skinning agents are incorporated into paint and coating formulations to improve application properties, film formation, and surface appearance. They help reduce surface defects, improve gloss, and prevent skinning during storage.

- Water Treatment: HHPA derivatives are utilized in water treatment formulations as scale inhibitors, corrosion inhibitors, and dispersants to prevent the buildup of scale, rust, and deposits in industrial water systems, cooling towers, boilers, and pipelines. They improve system efficiency and prolong equipment life.

- Food Packaging: HHPA-based resins and coatings are used in food packaging applications such as cans, containers, and coatings for paper and cardboard packaging. They provide barrier properties, adhesion, and heat resistance, ensuring the safety and quality of packaged food products.