HI! I’M ELEMENT AI.

Hydroxypropyl Methylcellulose

Product Description

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer with a wide range of industrial applications due to its unique properties.

Product:

Hydroxypropyl Methylcellulose

CAS:

9004-65-3

Synonym:

Hypromellose; 2-Hydroxypropyl methyl cellulose ether

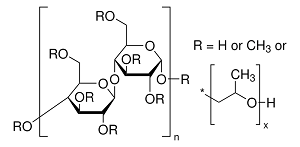

Structure:

Typical Characteristics

Appearance

White to off-white powder

Density

1.39 g/cm3

Melting point

225-230 °C

Molecular Weight

15000-300000

Odor

Odorless

Purity

99%

Refractive index

1.520

Uses, Applications & Markets

Key applications

get a quote

We Offer Hydroxypropyl Methylcellulose

in various grades

A few of the grades available are listed below:

Hydroxypropyl Methylcellulose used in many

industry applications

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer with a wide range of industrial applications due to its unique properties. Here are some of its key industrial uses:

- Construction: HPMC is commonly used in the construction industry as a thickener, water retention agent, and rheology modifier in cement-based mortars, plasters, tile adhesives, grouts, and self-leveling compounds. It improves workability, adhesion, and sag resistance, contributing to the overall performance and durability of construction materials.

- Pharmaceuticals: In pharmaceutical formulations, HPMC serves as a pharmaceutical excipient in tablet coatings, controlled-release matrices, suspensions, ophthalmic solutions, and topical creams. It provides film-forming properties, viscosity control, and drug release modulation, ensuring the efficacy, stability, and patient acceptability of pharmaceutical products.

- Food Industry: HPMC is used in the food industry as a thickener, stabilizer, emulsifier, and gelling agent in various food products, including sauces, dressings, bakery goods, ice creams, and dairy products. It helps improve texture, mouthfeel, and shelf stability while providing a clean label solution for food manufacturers.

- Personal Care Products: HPMC is found in a wide range of personal care and cosmetic products, such as shampoos, lotions, creams, and makeup, where it acts as a thickener, suspending agent, binder, and film former. It enhances product consistency, sensory attributes, and skin feel, making it ideal for use in cosmetics and toiletries.

- Paper Industry: In the papermaking process, HPMC is used as a surface sizing agent, coating additive, and retention aid to improve paper strength, printability, and surface smoothness. It enhances paper formation, reduces linting and dusting, and promotes ink adhesion, resulting in high-quality paper products.

- Textile Printing: HPMC is employed in textile printing pastes as a thickener and rheology modifier to control the viscosity and flow behavior of printing inks. It ensures precise ink deposition, sharp print definition, and color consistency during the screen or roller printing process, enhancing the quality and reproducibility of printed fabrics.

- Ceramics: In the ceramics industry, HPMC is used as a binder, plasticizer, and suspension agent in ceramic body formulations, glazes, and casting slips. It facilitates shaping, molding, and extrusion processes, improves green strength and drying characteristics, and prevents cracking and warping during firing, resulting in high-quality ceramic products.

- Adhesives: HPMC is incorporated into adhesive formulations as a thickener and rheology modifier to adjust the viscosity, tack, and open time of adhesives used in construction, woodworking, packaging, and other applications. It enhances adhesive bonding performance, substrate wetting, and overall application properties.