Acetyl Triethylhexyl Citrate

Product Description

Acetyl Triethylhexyl Citrate is a non-toxic, biodegradable plasticizer derived from citric acid. It is widely used in various industries due to its excellent compatibility with polymers and eco-friendly profile.

Product:

Acetyl Triethylhexyl Citrate

CAS:

144-15-0

Synonym:

Acetyl tris(2-ethylhexyl) citrate; 1,2,3-Propanetricarboxylic acid, 2-(acetyloxy)-, tris(2-ethylhexyl) ester; Tris(2-ethylhexyl); 2-(acetyloxy)propane-1,2,3-tricarboxylate

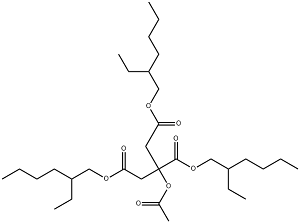

Structure:

Typical Characteristics

Appearance

Colorless oily liquid

Boiling point

228-229 °C/100 mmHg

Density

1.136 g/cm3

Melting point

-42 °C

Molecular Weight

570.80

Odor

Odorless

Purity

99%

Refractive index

1.439

Uses, Applications & Markets

Key applications

get a quote

We Offer Acetyl Triethylhexyl Citrate

in various grades

A few of the grades available are listed below:

Acetyl Triethylhexyl Citrate used in many

industry applications

Acetyl Triethylhexyl Citrate is a non-toxic, biodegradable plasticizer derived from citric acid. It is widely used in various industries due to its excellent compatibility with polymers and eco-friendly profile. Below are its key industrial applications:

- Plasticizer: Used as a primary plasticizer in PVC, bioplastics, and other polymer applications to enhance flexibility and durability.

- Cosmetics and Personal Care: Functions as a safe alternative to phthalate plasticizers in nail polish, perfumes, and skin care formulations.

- Medical and Pharmaceutical: Employed in medical-grade plastics for applications such as IV bags, tubing, and flexible medical devices due to its non-toxic nature.

- Food Packaging: Used in food contact materials and coatings to improve flexibility without releasing harmful chemicals.

- Adhesives and Sealants: Enhances the performance and elasticity of adhesives, sealants, and coatings in industrial applications.

- Printing Inks: Utilized as a plasticizer in ink formulations to improve adhesion and print quality.

- Coatings and Paints: Acts as a plasticizer in water-based and solvent-based coatings to enhance film formation and flexibility.

- Textile Industry: Used in textile treatments to improve softness and resilience of fabrics.

- Children’s Products: Preferred in toys and baby products as a safer alternative to traditional plasticizers.

- Agriculture: Used in biodegradable mulch films and other eco-friendly agricultural applications.