Carboxymethyl Cellulose

Product Description

Carboxymethyl cellulose (CMC), a versatile water-soluble polymer, finds various industrial applications owing to its unique properties.

Product:

Carboxymethyl Cellulose

CAS:

2593534

Synonym:

Carmellose; Cellulose, carboxymethyl ether

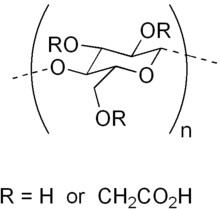

Structure:

Typical Characteristics

Appearance

White or light yellow powder

Density

1.050 g/cm3

Melting point

300 °C (decomposes)

Molecular Weight

50000-800000

Odor

Odorless

Purity

99%

Refractive index

1.51

Uses, Applications & Markets

Key applications

get a quote

We Offer Carboxymethyl Cellulose

in various grades

A few of the grades available are listed below:

Carboxymethyl Cellulose used in many

industry applications

Carboxymethyl cellulose (CMC), a cellulose derivative with carboxymethyl groups bound to some of the hydroxyl groups of the glucopyranose monomers, finds various industrial applications owing to its unique properties. Here's a list of some of its industrial uses:

- Food Industry: CMC is widely used as a thickener, stabilizer, and emulsifier in various food products, including ice cream, bakery items, dairy products, and sauces. It helps improve texture, consistency, and shelf life.

- Pharmaceutical Industry: In pharmaceuticals, CMC serves as a binder in tablet formulations, a suspending agent in liquid medications, and a lubricant in ophthalmic solutions. It enhances the stability and delivery of active ingredients.

- Cosmetics and Personal Care: CMC is used in lotions, creams, shampoos, and toothpaste as a thickening agent, stabilizer, and film-forming agent. It improves the viscosity and texture of these products.

- Textile Industry: CMC is employed as a sizing agent in textile manufacturing to provide strength and reduce fraying of fabrics during weaving. It also acts as a thickener in textile printing pastes.

- Paper Industry: In papermaking, CMC is used as a binder and coating agent to enhance the strength and surface properties of paper. It improves printability and reduces ink bleed-through.

- Oil Drilling: CMC is utilized in oil and gas drilling fluids as a viscosity modifier and water retention agent. It helps stabilize the drilling mud and prevent fluid loss in porous formations.

- Construction Industry: CMC is added to cement and plaster formulations as a water-retaining agent and workability enhancer. It improves the application properties and durability of these materials.

- Adhesives: CMC is used in the production of water-based adhesives for applications in packaging, labeling, and woodworking. It provides good adhesion properties and easy application.

- Detergents: In detergents, CMC acts as a soil suspending agent, preventing redeposition of dirt on fabrics during washing. It enhances the cleaning performance of laundry detergents.

- Ceramics: CMC is used in ceramic processing as a binder and plasticizer to improve the workability of ceramic bodies and glazes. It aids in the shaping and drying of ceramic products.