Soda Ash

Product Description

Soda ash, also known as sodium carbonate, is a versatile chemical compound with numerous industrial applications.

Product:

Soda Ash

CAS:

497-19-8

Synonym:

Sodium carbonate; Calcined soda; Carbonic acid disodium salt

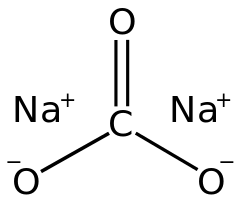

Structure:

Typical Characteristics

Appearance

White crystalline powder

Density

2.54 g/cm3

Melting point

851 °C

Molecular Weight

105.99

Odor

Odorless

Purity

≥99.5%

Refractive index

1.489

Uses, Applications & Markets

Key applications

Markets

get a quote

Soda Ash used in many

industry applications

Soda ash, also known as sodium carbonate, is a versatile chemical compound with numerous industrial applications. Here are some of its uses:

- Glass Manufacturing: Soda ash is a key raw material in the glass industry, where it is used as a flux to lower the melting point of silica sand. It helps facilitate the formation of glass and improves its clarity, strength, and durability. Soda ash is essential for the production of flat glass, container glass, fiberglass, and other glass products.

- Detergents and Cleaning Products: Soda ash is a major ingredient in the manufacture of detergents, laundry soaps, and cleaning products. It acts as a water softener, alkalinity builder, and pH adjuster in detergent formulations. Soda ash helps remove dirt, grease, and stains from fabrics and surfaces by enhancing the effectiveness of surfactants and cleaning agents.

- Water Treatment: Soda ash is used in water treatment processes to adjust pH levels, alkalinity, and hardness in municipal and industrial water systems. It can help neutralize acidic water, precipitate calcium and magnesium ions, and control corrosion in pipelines and equipment. Soda ash is also used in swimming pool maintenance to balance water chemistry.

- Chemical Manufacturing: Soda ash serves as a versatile chemical intermediate in various manufacturing processes. It is used in the production of sodium bicarbonate (baking soda), sodium silicate (water glass), sodium phosphates, and other sodium compounds. Soda ash is also employed in chemical reactions such as neutralization, precipitation, and pH adjustment.

- Textile Industry: Soda ash is used in textile processing for applications such as dyeing, printing, and finishing. It helps fix and enhance the coloration of fabrics by controlling pH levels and activating reactive dyes. Soda ash can also be used in textile desizing, scouring, and mercerizing processes to remove sizing agents and improve fabric properties.

- Metallurgy: Soda ash is utilized in metallurgical processes for ore flotation, ore refining, and metal extraction. It is added to flotation slurries to increase the pH and improve the recovery of valuable minerals from ores. Soda ash can also be used as a flux in smelting and refining operations to remove impurities and enhance metal purity.

- Chemical Analysis: Soda ash is used in analytical chemistry as a primary standard for acid-base titrations and pH calibration. It is often standardized against primary standard acids such as hydrochloric acid (HCl) or sulfuric acid (H2SO4) to determine their concentrations accurately. Soda ash solutions are also used in titration experiments to determine unknown concentrations of acids.

- Food and Beverage Industry: Soda ash is approved for use as a food additive (E500) and is used in food processing and beverage production. It may be added to certain food products as a pH regulator, buffering agent, or leavening agent. Soda ash is commonly used in baking recipes to activate baking powder and promote dough rising in baked goods.

- Paper and Pulp Industry: Soda ash is employed in the paper and pulp industry as a pH adjuster, alkalinity builder, and sizing agent. It helps control pH levels in pulp bleaching and papermaking processes, improve paper strength and brightness, and enhance the efficiency of chemical treatments. Soda ash is also used in paper recycling to neutralize acidic contaminants.

- Construction Materials: Soda ash is used in the production of various construction materials such as cement, concrete, and plaster. It can be added to cement formulations to improve workability, reduce setting time, and enhance durability. Soda ash is also used in the manufacturing of plasterboard, mortar, and grout for construction applications.