HI! I’M ELEMENT AI.

Polypropylene Wax

Product Description

Polypropylene wax, a type of synthetic wax derived from polypropylene, finds diverse industrial applications due to its unique properties and versatility.

Product:

Polypropylene Wax

CAS:

9010-79-1

Synonym:

PP wax; Ethylene-propylene copolymer

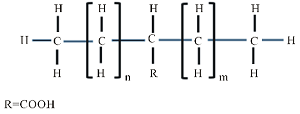

Structure:

Typical Characteristics

Appearance

White wax-like powder

Density

0.9 g/cm3

Flash Point

137 °C

Melting point

120-122 °C

Molecular Weight

1000-2000

Odor

Odorless

Purity

≥98%

Refractive index

1.5190

Uses, Applications & Markets

Key applications

get a quote

We Offer Polypropylene Wax

in various grades

A few of the grades available are listed below:

Polypropylene Wax used in many

industry applications

Polypropylene wax, a type of synthetic wax derived from polypropylene, finds diverse industrial applications due to its unique properties and versatility. Here are some of its notable industrial uses:

- Processing Aid: Polypropylene wax is widely employed as a processing aid in the production of various polymers, including polyethylene, polypropylene, and PVC. It acts as a lubricant and release agent during processing, facilitating smooth extrusion, injection molding, and calendaring processes while preventing adhesion to molds and equipment surfaces.

- Coating and Ink Additive: Due to its low viscosity and excellent compatibility with organic solvents and resins, polypropylene wax is utilized as an additive in coatings, paints, and printing inks. It imparts gloss, slip resistance, and scratch resistance to coatings, enhancing surface finish and durability.

- Textile and Leather Processing: In the textile and leather industries, polypropylene wax is utilized as a lubricant and softening agent in fiber spinning, weaving, and finishing processes. It improves yarn cohesion, reduces friction during weaving, and imparts softness and smoothness to textile and leather products.

- Plastic Additive: As a plastic additive, polypropylene wax functions as a nucleating agent and anti-blocking agent in polyolefin films and molded articles. It promotes uniform crystallization, reduces shrinkage and warpage, and enhances surface smoothness in plastic products.

- Adhesive Modifier: Polypropylene wax is incorporated into adhesive formulations to modify rheological properties, improve tack, and enhance adhesion to various substrates. It is commonly used in hot melt adhesives, pressure-sensitive adhesives, and sealants for packaging, woodworking, and automotive applications.

- Rubber Processing: In the rubber industry, polypropylene wax serves as a processing aid and release agent in the production of rubber compounds and molded rubber products. It facilitates dispersion of fillers and additives, prevents sticking to molds, and improves surface finish in rubber articles.

- Personal Care Products: Polypropylene wax is utilized in the formulation of cosmetics, skincare products, and hair care products as a thickening agent, emollient, and film-forming agent. It enhances product texture, provides moisturization, and imparts shine and gloss to personal care formulations.

- Food Packaging: Due to its low toxicity and inertness, polypropylene wax is used as a food-grade additive in packaging materials, such as food wraps, films, and coatings. It provides moisture resistance, heat sealability, and barrier properties, extending the shelf life of packaged food products.