Polyvinyl Butyral

Product Description

Polyvinyl butyral (PVB), a resin commonly used for its adhesive and film-forming properties, finds various industrial applications owing to its unique characteristics.

Product:

Polyvinyl Butyral

CAS:

63148-65-2

Synonym:

Vinyl butyral polymers; Vinyl acetal polymers; Poly[(2-propyl-1,3-dioxane-4,6-diyl)methylene]

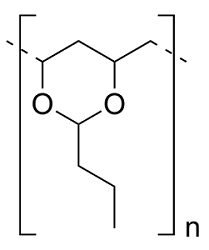

Structure:

Typical Characteristics

Appearance

White to off-white powder

Density

1.08 g/cm3

Melting point

165-185 °C

Molecular Weight

40000-120000

Odor

Odorless

Purity

98%

Refractive index

1.485

Uses, Applications & Markets

Key applications

get a quote

We Offer Polyvinyl Butyral

in various grades

A few of the grades available are listed below:

Polyvinyl Butyral used in many

industry applications

Polyvinyl butyral (PVB), a resin commonly used for its adhesive and film-forming properties, finds various industrial applications owing to its unique characteristics. Here's a list of some of its industrial uses:

- Laminated Safety Glass: PVB is widely used in the production of laminated safety glass for automotive and architectural applications. It provides excellent adhesion between glass layers, enhancing impact resistance and safety.

- Coatings and Paints: In the coatings and paints industry, PVB is used as a binder and film-forming agent, offering excellent adhesion, flexibility, and toughness to coatings.

- Solar Panels: PVB is employed in the encapsulation of solar panels, providing protection and stability to the photovoltaic cells, enhancing the durability and performance of the panels.

- Adhesives: PVB is used in the formulation of adhesives, especially in the production of high-performance adhesives that require strong bonding and flexibility.

- Printing Inks: PVB is used in the production of printing inks, providing excellent adhesion and flexibility to the printed materials, especially in packaging applications.

- Protective Films: PVB is used to manufacture protective films for various applications, offering excellent clarity, adhesion, and impact resistance.

- Composite Materials: PVB is used as a matrix resin in composite materials, providing enhanced mechanical properties and stability to the composites.

- Electronics: PVB is used in the electronics industry for encapsulation and protection of electronic components, offering good electrical insulation and mechanical stability.

- Packaging: PVB is used in packaging applications where clarity, flexibility, and durability are required, such as in the production of high-quality packaging films.

- Textiles: PVB is used in the textile industry for coating fabrics, providing water resistance, flexibility, and durability to the textiles.