Pharmaceutical & Fine Chemicals

Polyvinyl Pyrrolidone

Product Description

Polyvinyl pyrrolidone (PVP) is a versatile polymer with a wide range of industrial applications due to its unique properties, including high solubility, biocompatibility, and film-forming ability.

Product:

Polyvinyl Pyrrolidone

CAS:

9003-39-8

Synonym:

Poly-N-vinylpyrrolidine; Polyvidone; Povidone

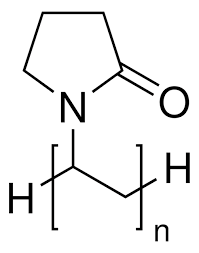

Structure:

Typical Characteristics

Appearance

White to light yellow powder

Density

1.23-1.29 g/cm3

Melting point

150 to 180 °C

Molecular Weight

2500 – 2500000

Odor

Odorless

Purity

99%

Refractive index

1.5300

Uses, Applications & Markets

Key applications

get a quote

We Offer Polyvinyl Pyrrolidone

in various grades

A few of the grades available are listed below:

Polyvinyl Pyrrolidone used in many

industry applications

Polyvinyl pyrrolidone (PVP) is a versatile polymer with a wide range of industrial applications due to its unique properties, including high solubility, biocompatibility, and film-forming ability. Here are some of its industrial uses:

- Pharmaceuticals: PVP is widely used in pharmaceutical formulations as a binder, disintegrant, and solubilizing agent in tablets, capsules, and topical formulations. It improves drug stability, bioavailability, and patient compliance.

- Cosmetics: PVP is utilized in cosmetics and personal care products as a film former, thickener, and stabilizer in hair care products, skin creams, and oral care products. It enhances product texture, viscosity, and shelf life.

- Adhesives and Sealants: PVP is employed as a binder and rheology modifier in adhesives and sealants formulations for various applications, including construction, packaging, and automotive industries. It improves adhesion and cohesion properties.

- Food and Beverage: PVP is approved for use as a food additive in some countries and is used as a clarifying agent, stabilizer, and thickener in food and beverage products. It helps improve product clarity, texture, and shelf stability.

- Textile Industry: PVP is used in the textile industry as a sizing agent, dye carrier, and fiber modifier to improve dye absorption, color fastness, and fabric strength. It enhances fabric performance and process efficiency.

- Coatings and Inks: PVP is incorporated into coatings, inks, and paints formulations as a film former, viscosity modifier, and dispersant. It improves coating adhesion, surface smoothness, and printability on various substrates.

- Biomedical Applications: PVP is utilized in biomedical and biotechnology applications, including wound dressings, drug delivery systems, and tissue engineering scaffolds. It exhibits excellent biocompatibility and water absorption properties.

- Photographic Films: PVP is used in photographic films and papers as a protective colloid, emulsion stabilizer, and antistatic agent. It helps prevent emulsion flocculation, improve film sensitivity, and reduce static charge buildup.

- Industrial Processes: PVP finds applications in various industrial processes, such as water treatment, metal extraction, and polymerization reactions, as a stabilizer, chelating agent, and dispersant. It enhances process efficiency and product quality.

- Ceramics and Composites: PVP is employed in ceramics and composite materials as a binder, dispersant, and pore-forming agent to improve green strength, rheological properties, and microstructure. It enhances material performance and processing.